How Is An LEV System Designed And Who Is Involved

There are a number of jobs where the work performed releases some type of airborne contaminate that could be harmful to the employees. This might include dust, debris, fumes, or vapour. It’s the obligation of the employer to ensure that these harmful contaminants are controlled and not allowed to enter the breathing zone of the employees. This is accomplished through the design and installation of local exhaust ventilation (LEV) systems. Many different LEV systems exist and they are designed for handling specific contaminants in specific environments.

The use of LEV systems is more than an employee preference. It is required by law and employees that do not meet the standards set forth in HSG-258 could find themselves facing serious trouble. Therefore, it’s ideal that all employers and employees understand these regulations as well as understand how LEV systems work.

The Parties Involved

There are generally five parties involved in the process of designing, installing, and using a LEV system. Those parties are as follows:

- Employer

- Employee

- Designer

- Installer

- Examiner

The first two parties are easy to understand. They are the employer, whose responsibility it is to protect his workers, and then the workers themselves. But there are three additional parties involved that need to be understood.

First, there is the system designer. This person is typically an engineer who has plenty of experience in the LEV design field. They are supplied information by the employer regarding various specifications of the system. For example, they need to know what type of contaminants are involved and the desired reduction in exposure. It’s important that receive accurate information because it can be very costly to correct errors once the LEV system has been built.

The designer will often produce a user manual for the system as well. This will help employers and employees better understand how the system operates. It is highly recommended that employers train their employees to work with the specific LEV system designed for their business. Accidental misuse of the system could result in unwanted contaminant exposure.

Prior to installation, the installer will work as a commissioner to test the accuracy, effectiveness, and reliability of the ventilation system. They may test the flow rate of air and make velocity measurements at various points in the system. It needs to be demonstrated that the ventilation system can fully perform its function as intended before it can be installed. There may be errors detected, which will require adjustments to be made by the designer.

Once the system has been accepted by the installer it can be installed in the workplace. This duration of the installation process will depend entirely on the size and complexity of the ventilation system. In general, does not take long to install an average-sized LEV system, but of course, complex systems will take longer as will installing multiple systems.

The final party involved is the examiner. Employers are required to have their LEV systems inspected regularly. The frequency of these inspections depends on the type of LEV and the contaminants that are being extracted. This information can be found in the HSG258 documentation. The examiner is a certified party who performs the examination. The examiner also tests the system against the original report provided by the commissioner prior to installation.

LEV System Components

The Hood

The primary component of any dust and fume extraction system is the hood. These are available in a large variety of sizes and shapes. Hoods are grouped together according to specific design factors. The three main categories are as follows:

-

- Captor hood

- Receiving hood

- Enclosing hood

Captor hoods are also referred to as external hoods. They are the most common hood type, though they are typically misused and not fully understood by the workers. This is often due to improper employee training for the particular system. The source of contaminants is always outside of the hood, which means that the hood needs a powerful source of airflow to pull in the contaminants before they reach the worker. Captor hoods are frequently used to control fumes from soldering irons and welders.

A receiving hood is somewhat similar to a captor hood in that the contaminant source is also located outside and away from the hood. The major difference between the two is that a receiving hood does not rely on airflow to pull in the contaminants. Instead, the contaminant is propelled into the hood by some force. For example, smoke rising from a hot surface would move into a receiving hood naturally. This is why they are very popular in commercial kitchens. Airflow may still be used to assist the process, though it does not need to be as powerful as with a capturing hood.

The final type of hood is the enclosing hood. These are the most effective containment method because the source of contaminants is actually located inside the hood itself. The enclosure may be a full enclosure, such as with a glove box, or a partial enclosure like a fume cupboard.

Enclosed hoods are typically more expensive and complex, but offer the highest level of protection. Fully enclosed hoods are the most effective. With a partially enclosed hood, the effectiveness increases as the size of the opening decreases.

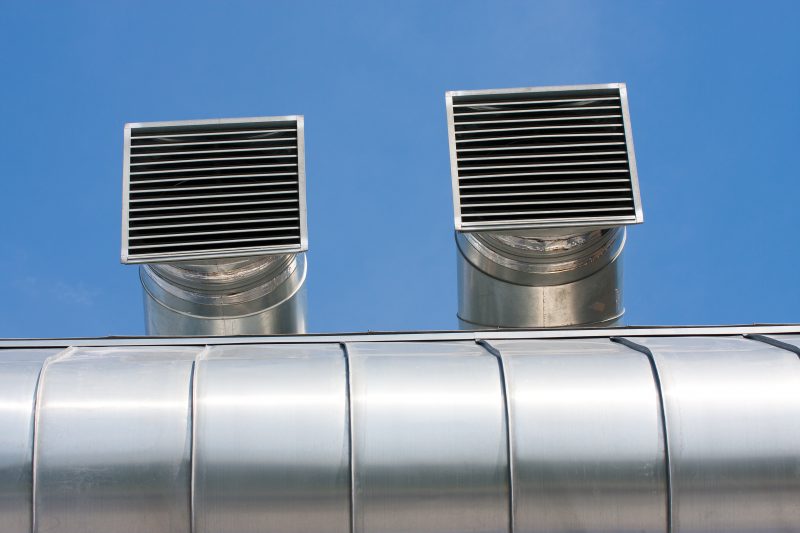

Additional LEV System Components

There are several additional components need to complete the LEV system. The primary components found in most systems include:

- Air Mover

- Ducts

- Air cleaner

The air mover is responsible for creating air flow through the ducts. This is most often a fan. The size and strength of the fan will depend on the size of the system as well as the type of hood. Capture hoods require the strongest fans.

The air mover pulls the contaminated air from the hood into the ducts. The ducts are used to connect various parts of the system. Typically, the ducts connect the hood to the air cleaner. There may be additional components along the way depending on the design of the system.

The final part of the system is the air cleaner. The specifics of this component will depend on the type of contaminant that needs to be removed from the air. There are many different air cleaners available and the LEV designer will know the best choice.

Together, these components create the standard LEV system. The components themselves are not very complex, but the system must be designed carefully and with specific parameters to ensure that it fully removes the contaminants from the breathing zone.