The Importance of using a Harness for Working at Height

39% of fatalities in construction-related activity in the USA are the result of falls that are the number 1 cause of work-related deaths in construction.

As working in the industrial sector for years, we have heard many companies just ask workers to get a harness out of the box for any kind of work. Stop doing it. Read this simple and comprehensive guide to harness and get the right gear for your hard graft!

Types of Safety Harness

Harnesses are used for various working-at-height functions, like fall arrest, ladder climbing, rescue, restraint and work positioning. Some serve one function and some can perform all. In order to achieve the required functions, you have to understand what each harness attachment point is used for. We asked experts Lakeside-hire.co.uk to explain all for us.

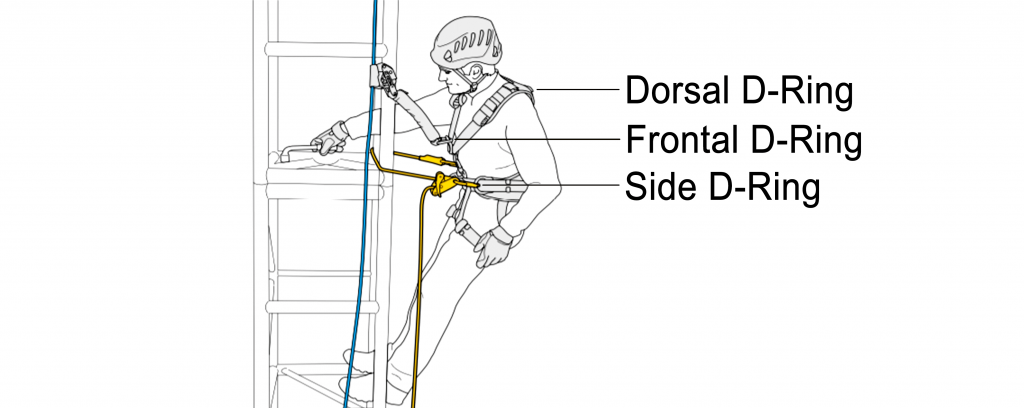

Attachment points are the connectors or called D-rings, joining the fall protection equipment such as safety lanyard to the user. Generally speaking, your work activities determine the types of harness attachment points required. Each point has a specific function(s) and the random connection is very dangerous. If your work is involved with work-positioning, a positioning lanyard is needed to connect the side/hip D-rings of your harness as opposed to the back D-ring or others.

Figure1. Some manufacturers supply construction harnesses with many D-rings and they seem straightforward to construction workers but the D-rings must be used properly.

Figure1. Some manufacturers supply construction harnesses with many D-rings and they seem straightforward to construction workers but the D-rings must be used properly.

Which Should we Choose, a 2-Point Harness, 3-Point or more?

1. Single-Point Harness

The dorsal D-ring on a single-point harness, is on the back and sits between the worker’s shoulder blades for fall arrest, fall restraint and rescue.

The dorsal D-ring on a single-point harness, is on the back and sits between the worker’s shoulder blades for fall arrest, fall restraint and rescue.

It can be attached to an energy-absorbing lanyard or self-retracting lanyard safety rope for fall arrest where an “arrest” occurs after a person freefalls through space. This system stops a worker from falling and reduces the fall-generated forces on the user.

When it comes to fall restraint, the worker is restrained from reaching a fall hazard so a fall will not occur. The fall restraint lanyard used in combination with your harness can prevent you from reaching the leading edge. Note: Don’t confuse fall restraint where a fall does NOT occur with fall arrest where a fall occurs.

This full-body harness is suitable for horizontal uses and the work that does not require rope length adjustment, e.g. burning roofing shingles.

2. 2-Point Harness

The 2 attachment points are on the back (Dorsal D-ring) and chest (Sternal D-ring).

Both are permitted for fall restraint and fall arrest. The Sternal D-ring is specifically designed for fall arrest on a fixed ladder climbing system* to prevent the user from falling. A dorsal D-ring cannot do so. In the recuse use and confined space such as sewers, fuel storage tanks and certain chemical storage vessels, they can be the applicable D-ring connections. It’s essential to carefully read the manufacturer´s user manual before use.

Both are permitted for fall restraint and fall arrest. The Sternal D-ring is specifically designed for fall arrest on a fixed ladder climbing system* to prevent the user from falling. A dorsal D-ring cannot do so. In the recuse use and confined space such as sewers, fuel storage tanks and certain chemical storage vessels, they can be the applicable D-ring connections. It’s essential to carefully read the manufacturer´s user manual before use.

*Climbing uses can be easily confused with work positioning that will be discussed next.

3. 3-Point Harness

With 2 shoulder D-rings for retrieval and one in the centre of the back for fall arrest, this type of full-body harness known as recuse harness is ideal for confined space entry and rescue/retrieval. It is very commonly used in the high-risk industries such as construction, mining and transportation.

With 2 shoulder D-rings for retrieval and one in the centre of the back for fall arrest, this type of full-body harness known as recuse harness is ideal for confined space entry and rescue/retrieval. It is very commonly used in the high-risk industries such as construction, mining and transportation.

By connecting rescue equipment to the shoulder D-rings of the fallen wearer, they can be raised or lowered to a safe area.

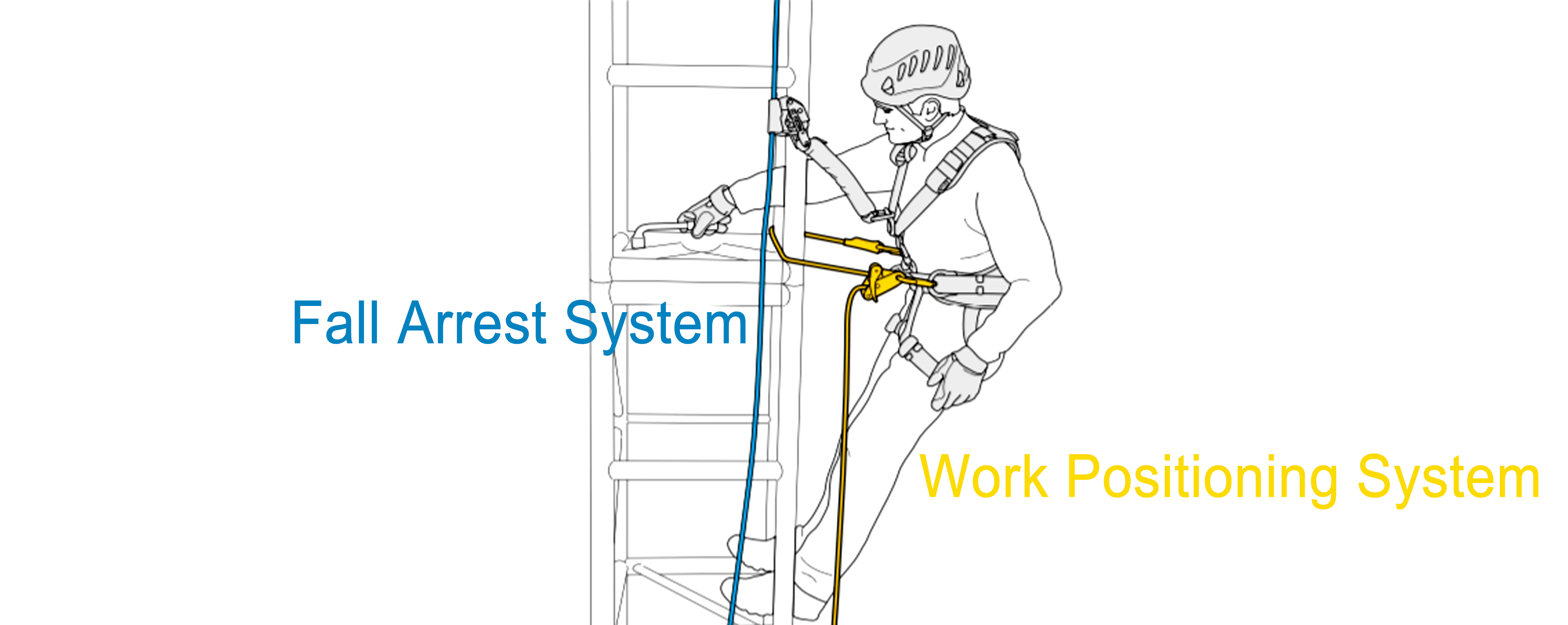

Another 3-point harness commonly named as work positioning harness features one dorsal point and 2 side attachment points. Harnesses of this kind include integral waist belts. In a work-positioning system, a positioning lanyard connects the side D-rings to an anchor like a rebar tower to support a user. It allows you to perform delicate tasks with two hands while maintaining stability at an elevated height. The role of the frontal D-ring we mentioned previously is NOT designed to hold you securely on the ladder for doing tasks with both hands.

Another 3-point harness commonly named as work positioning harness features one dorsal point and 2 side attachment points. Harnesses of this kind include integral waist belts. In a work-positioning system, a positioning lanyard connects the side D-rings to an anchor like a rebar tower to support a user. It allows you to perform delicate tasks with two hands while maintaining stability at an elevated height. The role of the frontal D-ring we mentioned previously is NOT designed to hold you securely on the ladder for doing tasks with both hands.

Figure2. A work positioning system should NOT be the only fall protection mean. It must be combined with a Fall Arrest system to ensure safety when working at height

Figure2. A work positioning system should NOT be the only fall protection mean. It must be combined with a Fall Arrest system to ensure safety when working at height

4. 4-Point and 5-Point Harness

A 4-point harness features D-rings on the back and front as well as on each side for work-positioning. A 5-point harness has an additional one on the abdomen to allow forces to be distributed evenly on 5 points to prevent serious injury.

Summary of the attachment point/D-ring applications

Dorsal (Back) D-ring: Fall Arrest, Fall Restraint, Rescue

Sternal (Front) D-rings: Ladder climbing, Fall Restraint, Rescue

Side D-rings: Work Positioning, Fall Restraint

Shoulder D-rings Confined entry/Retrieval harness, Fall Restraint

Once again, don’t think the more attachment points, the safer. Having more D-rings comes with the responsibility of knowing when they can and cannot be used. Using the wrong D-rings does not only fail to perform activities but also costs you your life.

Other Factors to be Considered when Choosing Harness for Working at Height

Apart from the right number of attachment points, size and comfort carry much weight when it comes to buying a harness for working at height.

1. Size

Many manufacturers nowadays produce safety harnesses that fit all users. However, universal sizing is not for all wearers even harnesses can be adjusted. The right-size harness should be snug fit but not tight and you can slide a flat hand between your leg and the leg strap.

2. Comfort

If you work long hours suspended on a harness, a high level of moisture will be trapped to cause discomfort. The harness made of breathable material can keep you dry and comfortable as well as protecting you from contracting heat-related illnesses. Well-padded straps can also make you work comfortably.

3. Bonus Tip #1

Some harnesses on the market are incorporated with extra features e.g. hi-vis gilet and life jacket. They are worth serious consideration because your job is exposed to a fall but it does not mean fall is the only hazard to be worried. Do you happen to work in low-light conditions or get drowned when working at height?

4. Bonus Tip #2

Not all standard safety harnesses can fulfil certain highly-specialized jobs like electricians and welders. Electrician’s Harness: When you are looking for an electrician’s harness, you have to make sure the harness provides electrical shock protection, preventing you from being exposed to electrical current.

Welding Safety Harness: Harnesses made of flame-retardant materials such as Kevlar are an option for workers who weld, burn or perform other types of hot work.

Safety Harness Inspection

A construction worker got injured seriously this year after falling 30’ from a scaffold in Fort Lauderdale. He was wearing a harness when he fell and many thought that it was caused by equipment failure. It brings to this section – INSPECTION. According to OSHA and ANSI,

‘’OSHA 1926.502(d)(21): Personal fall arrest systems shall be inspected prior to each use for wear, damage and other deterioration and defective components shall be removed from service.’’

‘’ANSI A10.32-2012: All fall protection equipment shall be inspected at least every six months after initial service by a competent person.’’

To learn more about when you should replace your harness, please read safety harness inspection blog that comes with the Full Body Harness Inspection Checklist.