Maintaining the Integrity of Perishable Goods with Cold Chain Asset Monitoring

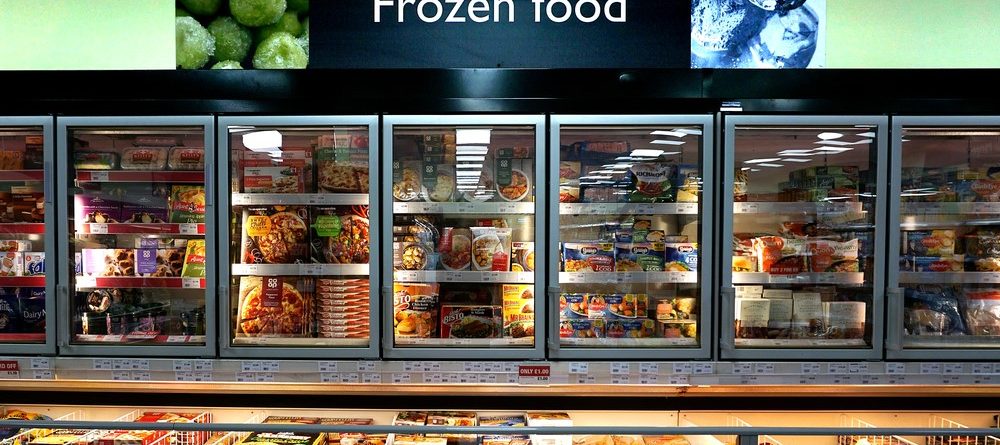

Handling and transporting perishable goods come with a myriad of problems. Due to their delicate nature, these goods have to be transported in temperature-controlled environments, making logistics operations infinitely more complex. Perishable goods are liable to spoil if the conditions in the cargo hold aren’t adequately monitored and controlled, and there’s nothing worse than finding an entire shipment of goods completely unusable upon delivery. With tens to thousands of vehicles transporting different types of temperature-sensitive cargo, transport and logistics companies require some form of automated checks to ensure their cargo arrives in optimal condition. Remote temperature monitoring systems use wireless Bluetooth sensors to detect temperature levels in real-time, and GPS-based transmitting devices to send the information to the cloud. Cold chain asset monitoring systems form a pattern in the data by analysing the trends. With actionable data at hand, field managers can automate certain procedures and set up alarms for emergencies or when a shipment needs urgent attention.

Cold chain asset monitoring systems are extremely reliable and provide crucial data for planning more efficient logistics operations while protecting the integrity of shipments until they reach their destination. In today’s world; it is useful to have a system in place that can detect, record and report any fluctuations in temperature levels, especially considering the volume of business operations and the slim margin for error within them. Let’s take a look at why so many businesses find these systems mandatory for operation management.

1-Traceability of Perishable Goods

It’s easy to lose track when managing hundreds of vehicles and assets spread out over large areas. However, failing to maintain a stable connection with your vehicles can lead to significant issues down the road. Even if wireless sensors detect a drastic change in temperature, field managers can’t step in and resolve the problem if they can’t trace the source. Cold chain asset monitoring systems provide regular location updates and enable any given vehicle to be located and tracked in real-time. In the event of an accident, breakdown or malfunction, executives with access to the tracking servers can limit downtime by quickly sending a replacement vehicle or roadside assistance, depending on the severity of the situation. With their advanced geolocation capabilities, cold chain monitoring systems are perfectly suited for ensuring long-distance logistics operations are executed flawlessly.

2-Wireless Sensors

2-Wireless Sensors

Wireless Bluetooth sensors take on the important task of monitoring the precious cargo onboard temperature-regulated vehicles while en route. These sensitive wireless sensors can detect even the slightest change of temperature inside the cargo hold and send out automated alerts if it exceeds the designated limits. Instant notifications enable managers to interfere and prevent an otherwise disastrous situation, ensuring that the delicate cargo arrives in optimum condition. These Bluetooth temperature sensors can be installed within minutes and immediately start collecting information about the vehicle’s cargo hold. When combined with a GPS tracking device that collects and transmits data about the vehicle’s location, speed, direction and driver performance, these small and effective devices give managers a greater sense of control over their entire business operation.

3-Monitoring and Reporting Capabilities

Cold chain logistics systems are designed to solve the real problems that transport and logistics companies face on a daily basis. The vast amount of data acquired by onboard sensors and tracking devices can be used to reduce operational costs and prevent waste. Every day, cold chain supply companies have to deal with innumerable issues related to the sensitive nature of their cargo. However, with the incredible advances in the field of GPS over the last ten years that have made these systems faster, smaller, lighter, cheaper and more reliable, businesses of all sizes can now take advantage of sophisticated temperature monitoring systems to remotely monitor their perishable goods. Not only are these systems extremely useful in emergency situations, but they also collect a surprising amount of data that can be used to generate proof-of-service reports and ensure regulatory compliance. Many governments require businesses to comply with their regulations, especially when dealing with temperature-sensitive pharmaceuticals, food products or other perishable goods. Historical temperature data records can be used to ensure compliance with these regulations, while at the same time identifying areas of improvement and delivering a seamless operation.

4-Viable for Different Industries

One of the biggest misconceptions regarding cold monitoring systems is that they have limited use for a few select types of business. This couldn’t be further from the truth. Exponential growth in the world population means there is an ever-increasing demand for temperature-sensitive food, medicine and other goods around the globe. It’s a logistical nightmare to transport perishable cargo without damaging its integrity; this is where cold chain monitoring systems enter the fray. Pharmacies, hospitals, laboratories, food service, hospitality, warehouses, and many other similar organisations all rely on remote temperature monitoring systems to transport their products and goods safely.

Whether shipping vaccines or processed meat, temperature-sensitive cargo has to be monitored around the clock. A slight change in weather conditions or a malfunction in the cooling system can have devastating consequences if not dealt with immediately. Luckily for business owners and executives, cold chain monitoring systems offer the best tools on the market for supervising complex cold chain supply operations. The market for cold chain asset monitoring systems is expected to reach almost £5 billion by 2023; this growth can be attributed to the increasing demand for high-quality food and beverages, temperature-sensitive pharmaceuticals and other industries that require highly-regulated environments such as livestock transportation. Intelligent cold chain monitoring solutions can make a massive impact on the business practices of a company. Employing these powerful systems can increase profitability by minimising the spoilage of shipments and increasing the quality of service, with on-demand access to actionable data.

Whether shipping vaccines or processed meat, temperature-sensitive cargo has to be monitored around the clock. A slight change in weather conditions or a malfunction in the cooling system can have devastating consequences if not dealt with immediately. Luckily for business owners and executives, cold chain monitoring systems offer the best tools on the market for supervising complex cold chain supply operations. The market for cold chain asset monitoring systems is expected to reach almost £5 billion by 2023; this growth can be attributed to the increasing demand for high-quality food and beverages, temperature-sensitive pharmaceuticals and other industries that require highly-regulated environments such as livestock transportation. Intelligent cold chain monitoring solutions can make a massive impact on the business practices of a company. Employing these powerful systems can increase profitability by minimising the spoilage of shipments and increasing the quality of service, with on-demand access to actionable data.