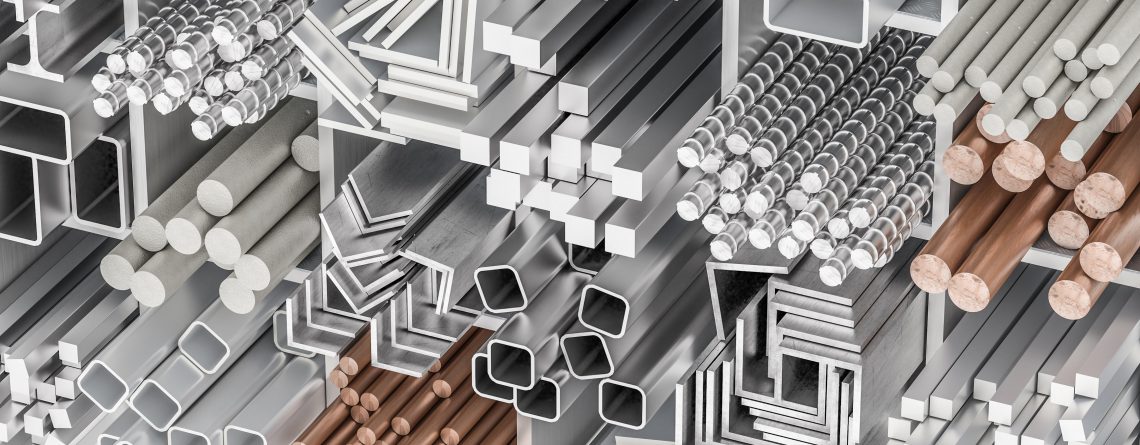

A Guide to Prefabricated Steel Construction Materials

There are two ways of looking at prefabricated steel construction materials; prefabricated steel reinforcing and prefabricated steel structures. The prefabricated steel reinforcing is reinforcing that has already been designed and all the loose and shaped steel have been welded or tied together to form a cage, that can easily be placed before concrete is poured. Prefabricated steel structures are modularised and panelised steel structures used to create bigger structures like commercial and industrial warehouses, sheds and aeroplane hangars.

Why use prefabricated steel construction materials?

Steel construction materials have been used in the construction industry for as long as there has been steel and construction, however prefabricated steel is becoming more and more popular. Prefabricated steel cuts down on on-site assembly time, which in turn speeds up productivity. Prefabricated steel pieces are designed ahead of time and manufactured off-site, because of this there are fewer mistakes made and there is less waste which costs money and negatively affects the environment. So while prefabricated steel might seem more expensive than buying loose steel pieces it ends up saving in the long run.

Types of Prefabricated Steel Reinforcement Cages

There are two main types of prefab steel reinforcement cages; standard prefabricated cages and pile cages.

Prefabricated Steel Cages

Prefabricated Steel Cages are steel reinforcing used in beams, columns and floor slabs. These cages can also be designed and used as pile caps, raft foundations and diaphragm wall cages. The cages have been designed and welded together to form a square or rectangular steel cages, or custom shapes according to an engineer’s schedule. The cage is constructed using steel straights and rectangular links just as you would construct your reinforcing on-site, but this is all done at the factory. In the case of a curved reinforcing, this too can be achieved with prefabricated steel cages. Once the design has been finalized and been made, it is then delivered to the site where all that is left to do is place your spacers, drop the reinforcing in the correct position and pour your concrete. Prefabricated steel cages allow for higher accuracy, less wastage and lots of time saved.

Prefabricated Pile Cages

Prefabricated pile cages are similar to prefabricated steel cages however they are circular in shape. They can be used for CFA piles, contiguous bored piles for retaining walls, mini piles, end-bearing piles and friction piles. These cages are constructed using steel straights and helical or circular links. Once the pile has been bored, the cage sections are then fed into the bore in sections with the spacers attached. Pile cages should not be stacked more than two high when stored, any more than two high compromises the cage shape. Pile cages are delivered in sections because piles can be extremely deep and it is a logistical nightmare to transport something that long to site.

Prefabricated Steel Structures

Prefabricated steel structures are modular and panelled structures that can be assembled on-site quickly. These structures come in a variety of sizes and shapes and therefore can be custom made to suit your needs. The steel comes in galvanised or painted finishes, which prevents any corrosion that might happen. Prefabricated steel structures are used for workshops, garages, agricultural purposes as well as industrial and commercial warehouses.

Because they are so quick to assemble, they are cost-effective and well as time-efficient. They are durable and are able to withstand extreme temperatures and high winds. The structures are very easy to extend and reduce to suit your needs which also makes them environmentally friendly because they are easy to disassemble and move to a new location. Their sustainability is a step in the right direction for the construction industry. These types of structures are gaining more and more popularity because of how easy it is to erect them and then move them again.

Prefabricated steel structures are also able to replace below ground in-situ poured concrete. Steel fabrication below ground structures is used as a below-ground structure that can be used for a variety of things like cellars, lift pits, sumps, tanks or any part of a facility that has a below-ground substructure. A steel structure is fabricated off-site in a factory setting and then shipped to the site and lowered into the demarked area. It is then backfilled with earth and concrete between the substructure and the trench walls. Because it has been welded together, it is airtight.

Prefabricated steel construction materials have a lot of benefits for the construction industry. They allow for certain jobs to be completed a lot faster and while they may seem expensive upfront, they work out cheaper in the long run. Prefabricated steel construction materials go a long way towards sustainability in the industry and cutting down unnecessary waste.